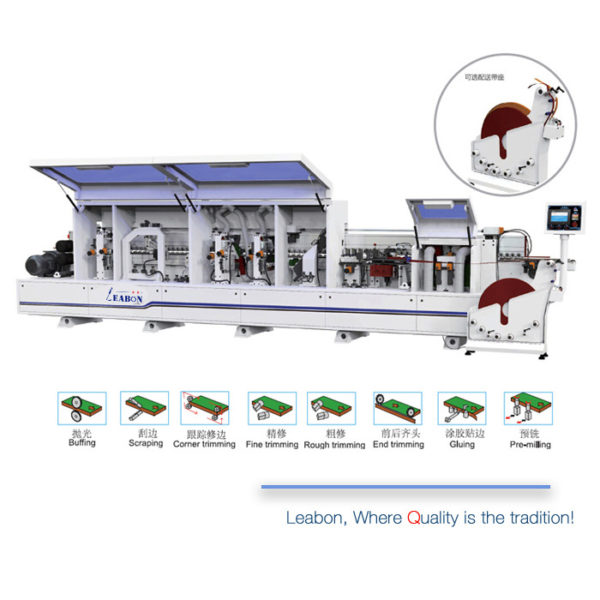

Full Automatic Edge Banding Machine T-600GY

T600GY Full Automatic Edge Banding Machine Main Features

1. Our automatic edge banding machine use Taiwan Delta/Invt. frequency controller, insured the duration and precision of our banding machine.

2. PLC use Taiwan Delta brand, air cylinder use Airtac from Taiwan, INNA liner track, Honeywell limitation switch, all key parts we choose market tested best brands to try to guarantee our machine performance and let our customers can enjoy to use our machines.

3. Independent lifting up and down system, simple and convenient.

4. Precise encoder control, high speed.

5. Special polishing structure, motor angle can be universal adjusted, make the PVC/Acrylic/ABS/Veneer band polishing and buffing to the best.

6. The glue spray cleaning system is optional and is good for removing glue and dirt from MDF/plank during the plastic edging process.

7. This model is full automatically including functions of gluing, pre milling, end cut, rough trim, fine trim, corner trim/rounding, scrapping, buffing.

8. With such powerful functions and high efficiency, our full automatic edge banding machine price is very competitive. As professional woodworking machine manufacture in China, We give factory price direct to final customer, when you buy, you save!

Automatic Edge Banding Machine T-600GY

Foreign customers watch the edge banding machine

Edge Banding Machine Control Panel

Corner Trim Part

WORKSHOP PRACTICE

Equipped with double diamond blades, remove the possible waving texture on edge to achieve better edge banding affection.

Click edit button to change this text.

PRE-MILLING AND END TRIM

The buffing device adopts cotton material polishing wheel to sand the finished edge band more smoothly.

The gluing equipment adopts a special structure to distribute the glue evenly on the tape panel and the tape to ensure a stronger adhesion.

BUFFING AND GLUING

Fine and rough trim facilities are used to remove the extra material on band, it adopts mould automatically track and high frequency high speed motor, ensure the plain and smooth of work piece top and bottom parts.

Scraping units used to remove the texture which might happened during trim processing, guarantee the band to be smooth and plain.

FINE TRIM / ROUGH TRIM AND SCRAPPING

Product Description

T-600GY Automatic Edge Banding Machine with additional functions such as edge trimming and pre-milling, this efficient edge bander is ideal for all your wood, MDF, plywood and other material edge banding requirements. Whether you are looking for edging kitchen c abinets, wardrobes , desks or any other furniture, the T-600GY provides the perfect finish for all types of edging materials including PVC, acrylic, veneer and more.

At the heart of the T-600GY is an advanced technology system utilizing Taiwan Delta inverter and PLC components to ensure durability and precision. Key components such as cylinders adopt Taiwan Airtac, INNA linear guide rails, and Honeywell limit switch es, all of which have been Strictly tested by the market and their performance is guaranteed.

An independent lift system makes operation easy and convenient, while precise encoder control provides high-speed performance for all your edgebanding needs. The machine's special polishing structure allows the motor angle to be adjusted to achieve the best results when pol ising PVC, acrylic, ABS, veneer and other edge banding materials.

For added convenience, the T-600GY can also be equipped with a glue spray cleaning system, ideal for removing any glue or dirt on MDF or sheet during edge banding.

In conclusion, T-600GY Automatic Edge Banding Machine is the perfect solution for all your edge banding needs. Its advanced technology, precise controls, and convenient features make it ideal for furniture makers, cabinet makers, and anyone looking for a high- performance edge bander.

OUR CERTIFICATES

| Model . | T600GY |

| Motor Power | 16.5Kw |

| Overall size | 7100*1000*1600mm |

| Feeding Speed | 12-20mm/min |

| Panel Thickness | 12-60mm |

| Edge banding tape thickness | 0.4-3mm |

| Panel Width | ≥80mm |

| Working air pressure | 0.6Mpa |

| Weight | 2800kgs |