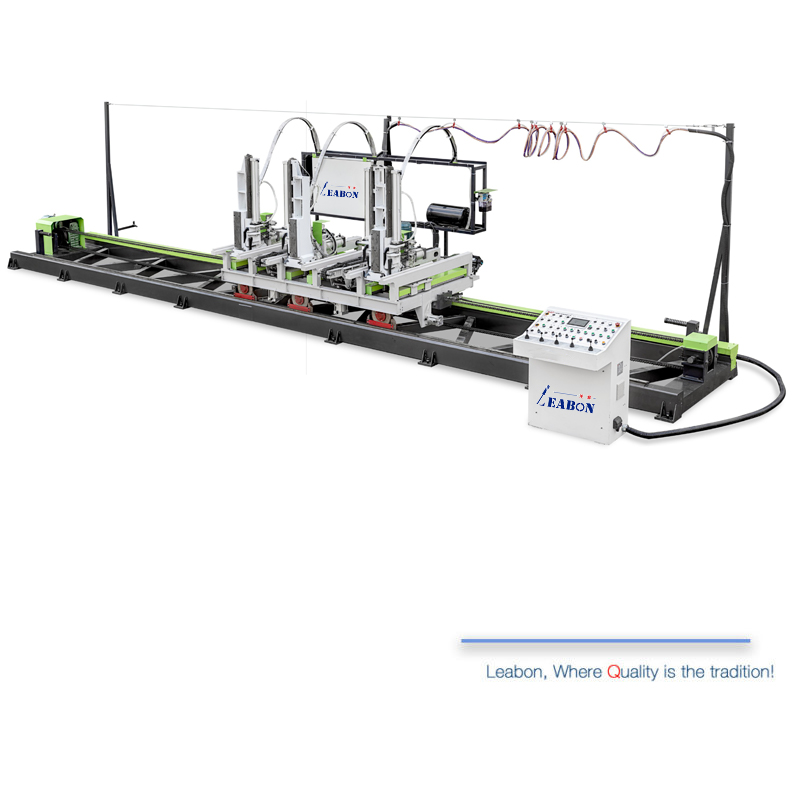

Double and Three-row CNC Mortising Machine for Efficient Drilling and Slotting Milling Multi-Station Simultaneous

Features of CNC Mortising Machine

1, It adopts advanced numerical control system, which is convenient to adjust and easy to learn.

2, No need to program, take the tool bar to take the point, you can generate the machining program to ensure the workpiece machining position is accurate.

3, high processing efficiency; multi-axis multi-station processing, left and right work station uninterrupted cycle processing.

4, The application of a wider range, suitable for processing a variety of different shapes, different specifications of the groove work.

5.It has significant advantages in the processing of complex special-shaped workpieces with multiple tongue and groove, small hole and groove combination of tongue and groove spacing, and different length and depth of tongue and groove on the same workpiece.

PARTS PICTURES

Taiwan billion map system, editing is easy to learn and understand.

Taiwan Delta inverter, one-to-one control high frequency motor.

France schneider electric components.

Germany imported guide rail, steel cover design protection slider.

Dust control button.

Select Delta servo drive motor.

Introduction

Introducing our CNC Mortising Machine, designed to provide efficient and accurate processing of grooved workpieces of various shapes and specifications. With its advanced numerical control system, our machine is easy to adjust and learn, making it an ideal choice for those seeking seamless and uninterrupted processing.

Our CNC Mortising Machine eliminates the need for programming, as users can simply take the tool bar to generate the processing program, thereby ensuring the accurate processing position of the workpiece. This feature is essential for processing complex special-shaped workpieces with multiple tongues and grooves, combinations of small tongue and groove spacing, and tongues and grooves of different lengths and depths on the same workpiece.

The scope of application for our CNC Mortising Machine is wide, and it is suitable for all manner of grooved workpieces. Moreover, the machine has significant advantages in processing grooved workpieces that require high precision and accuracy. Its multi-axis and multi-station processing capabilities make it possible to perform uninterrupted cycle processing of left and right stations, thereby enhancing processing efficiency.

Our CNC Mortising Machine was designed with the needs of businesses in mind. It provides fast and efficient continuous milling, multi-station simultaneous machining of holes and grooves, which greatly improves processing efficiency. What's more, after one group of workpieces is processed, another group can be clamped at the same time, enabling businesses to achieve better productivity levels.

In conclusion, if you're looking for a reliable and efficient CNC Mortising Machine that can handle all your grooved workpiece processing needs, look no further than ours. We guarantee accuracy, precision, and quality in every workpiece processed by our machine. Contact us today to learn more about what our CNC Mortising Machine can do for your business.

OUR CERTIFICATES

| Model | JR-3015-5A | JR-3725-5B |

| Processing range | 3200*140*200 | 3200*140*200 |

| Spindle power | 2.2KW/3.7KW | 2.2KW/3.7KW |

| Spindle speed | 18000r/min | 18000r/min |

| Equipment power | 24KW/35KW | 24KW/35KW |

| Processing speed | 1-15M/min | 1-15M/min |

| Return speed | 50M/min | 50M/min |

| Dimensions | 4200*2200*2200 | 4200*2200*2200 |

| Weight | 2.9T | 3.2T |