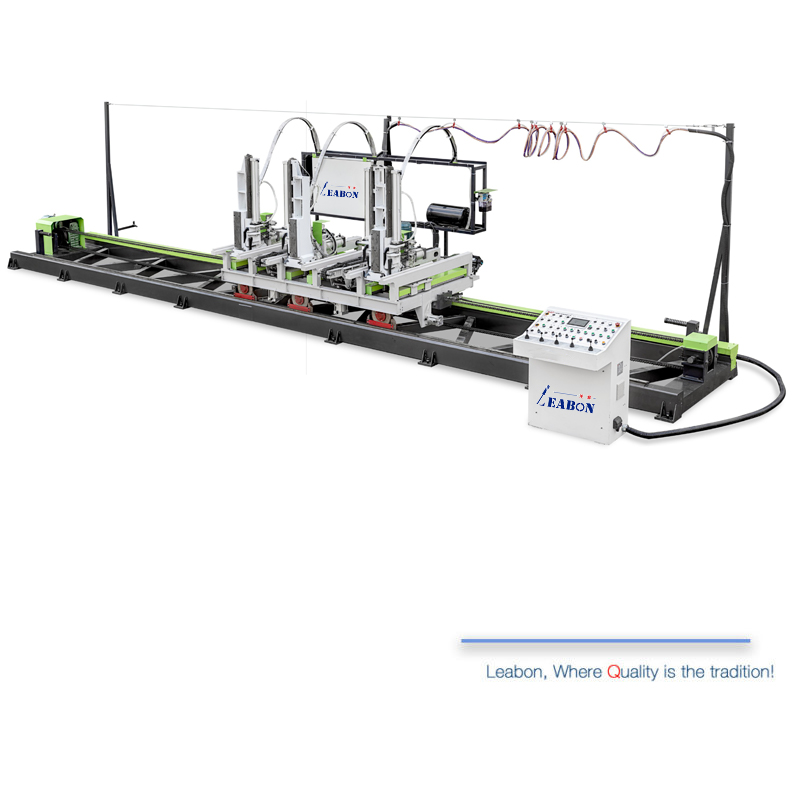

High Quality Cnc Side Drilling Machine Automatic Side Hole Cnc Wood Edge Wood Cabinet Edge Drilling Machine

Features of Cnc Woodworking Side Hole Drill Machine

1. This product is suitable for custom-made furniture sided ring equipment, used for horizontal drilling applications of various man-made panels, solid wood panels, and semi-solid wood panels.

2. It is an economical and simple processing equipment with easy operation and fast drilling speed.

3.Greatly improve the processing capacity and production efficiency by shortening the auxiliary working time. In addition, it reduces the number of traditional machine tools, saves the number to operators and reduces the floor area of the workshop.

4.Improve processing capacity and production efficiency. Improve wood production.

PARTS PICTURES

Working table

The use of wear-resistant PVC avoids the error caused by the wear of the table and effectively guarantees the accuracy.

Machine framework

The whole fuselage is plastic-sprayed, anti-corrosion and anti-rust, protecting the fuselage frame and prolonging the service life.

Pressure cylinder

Multi-axis support, uniform force, more firm pressing.

Solenoid oil pump

The oiler automatically injects oil to protect the operation of the machine and prevent the machine from being damaged due to manual forgetting to add oil.

Machine drill bag

Servo motor control is used to ensure the accuracy and efficiency of drilling.

Drive chain

High-speed operation is sensitive, low noise and vibration, accurate positioning, pressure resistance and wear resistance.

Introduction

CNC Woodworking Side Hole Drill Machine, an efficient and cost-effective solution for custom-made furniture edge rings. Designed for various wood-based panels, solid wood panels, and semi-solid wood panels, this machine is capable of handling all drilling applications with its fast drilling speed and convenient operation.

One of the standout features of this equipment is the ability to shorten the auxiliary working time. By reducing the need for traditional machine tools, the machine is able to save the number of operators and decrease the floor space of your workshop. This results in a massive improvement in processing capacity and production efficiency, ultimately leading to a significant increase in wood production.

The CNC Woodworking Side Hole Drill Machine is an economical and practical horizontal hole drilling equipment for panel furniture. It is perfect for those looking to save time, money, and resources in their production process. The machine does not require constant ruler adjustment, making the drilling process more efficient and streamlined.

Our dedicated intelligent furniture design and production software perfectly combines with this machine, allowing for truly intelligent production. With its advanced technology and smart features, this equipment brings your woodworking capabilities to new heights.

In summary, the CNC Woodworking Side Hole Drill Machine is an indispensable machine for furniture makers looking to improve their production efficiency. It provides fast and convenient drilling solutions, ultimately leading to increased wood production and significant cost savings. Get yours today and experience the benefits of intelligent production.

OUR CERTIFICATES

| Model | CKZ-300 |

| Max.processing length | 2440mm |

| Optional max. processing length | 2800mm |

| Max.processing thickness | 70mm |

| Max.processing width | 1220mm |

| Feeding speed | 2840r/min |

| Voltage | 380v |

| Total power | 4.5kw |

| Overall size | 3000x1900x1400mm |

| Weight | 1500kg |