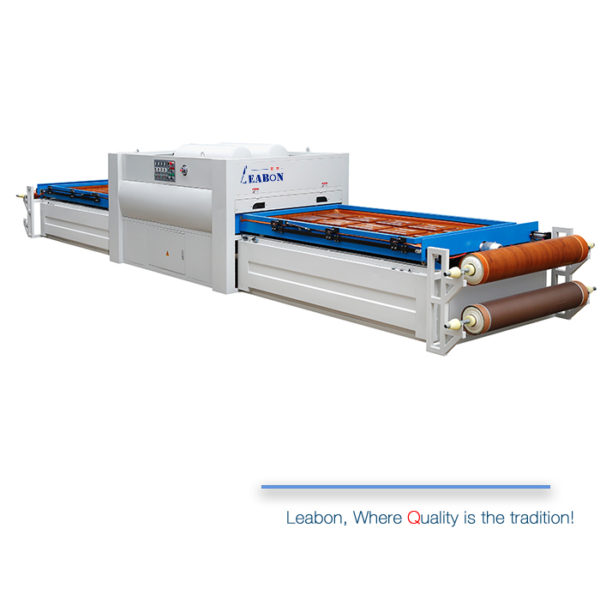

Vacuum press machine TOP-F280

TOP-F280 lamination vacuum press machine Features

1)TOP-F series models are the latest updated version.

The improvements are primarily reflected in:

1.It reduces the cumbersome operation steps and saves time;

2.Reduces the traditional trouble points and improves the working efficiency;

3.Improved quality of all major components to improve stability

4) This model is a double stations automatic operation mode. It can continuously operate the left and right two working tables. Maximize productivity without wasting time.

5) Using PLC control system, the man-machine interface is easy to operate. The original machine has been built into a variety of functional modes and a variety of parameter options, which can be freely selected at any time according to the PVC film of different materials. The multi-function mode effectively solves the phenomenon of PVC material rupture and insufficient linear coating in the process of suction and overmolding.

6)It equips with a high-speed vacuum pump with a rated speed of 140m³/h(optional) and an oversized vacuum tank. Therefore, the required pressure can be reached in a short time, and the pumping speed is fast. Shorten molding time and improve work efficiency.

7) Equipped with multi-functional suction-covering modes, namely: low-pressure suction-covering and high-pressure suction-covering modes, which can solve the phenomenon of PVC film wrinkling, film rupture and watermark surface. It better improves the yield of the product and the surface texture after lamination.

8) Equipped with a special electric heating aluminum plate, the upper and lower double heating can make the PVC film and the plate heated on both sides, and the heat dissipation is more uniform. Effectively improve the edging quality of the panels and control the deformation of the panels; equipped with high-quality aluminum silicate thermal insulation materials, heat insulation and fire prevention, and excellent thermal insulation effect.

Quick press frame

Hubble lenses are made from high-grade methafilcon A hydrogel material. With 55% water content, UV protection, and a thin edge, they’re designed for easy insertion, all-day comfort and crystal clear vision.

Control Panel

The operation interface is controlled by digital display, which is easy to understand. In addition,according to the PVC film of different materials, adjust the corresponding parameters (the parameter table is provided for reference when leaving the factory),In short,it can just press the start button when working, which is quick and time-saving.

High speed direct connection motor

The worktable runs with high-speed direct-connected motor drive and fequency control. Therefore,the method of decelerating and stopping at high speed effectively prevents the plate displaced. In addition,it also shortens the running time and improves work efficiency.

Pipeless connection device

To clarify, the configuration of the pipeless connection device solves two problems: 1. In the case of cold weather, the traditional steel wire hose is easy to break because it doesn’t against freezing; 2. The traditional vacuum steel pipe has long-term wear and abrasion, Easy to scratch and cause air leaks.

Floating up heating way

It equips with the function of floating and heating of PVC film, which can solve the phenomenon of wrinkles or shaded area on the middle and low grade soft PVC film, and improve the uniformity of heat on the surface of PVC film.

High speed vacuum pump

It equips with a high-speed vacuum pump with a rated speed of 100m3/h (optional) and an oversized vacuum tank. Therefore, the required pressure can reach in a short time, and the pumping speed is fast. So, shorten the molding time and improve the working efficiency.

High speed vacuum pump

It equips with a high-speed vacuum pump with a rated speed of 100m3/h (optional) and an oversized vacuum tank. Therefore, the required pressure can reach in a short time, and the pumping speed is fast. So, shorten the molding time and improve the working efficiency.

Introduction

Introducing the brand new TOP-F series special-shaped laminating machine, incorporating advanced features to provide unprecedented performance with smooth and efficient operation.

The TOP-F280 vacuum press machine is a must-have for any panel home improvement customization industry. This machine can stick high-grade PVC film, transfer film, and other decorative materials on the surface of various wooden boards with ease. It can also cover leather, wall covering, and veneer after adding silicone film. With such versatility, there is no limit to what you can create with ease.

The TOP-F280 is widely used in the door panel decoration production of cabinets, hinged doors, bathroom cabinet doors, computer desks, office furniture, and much more. The machine is designed to maximize productivity without wasting time. This model is a double stations automatic operation mode that can continuously operate the left and right two working tables. This maximizes the machine's capabilities and ensures high throughput in any production environment.

Equipped with a special electric heating aluminum plate, the TOP-F280 can offer upper and lower double heating that makes the PVC film and the plate heated on both sides. This ensures that heat is distributed more uniformly and effectively improves the edging quality of the panels. The machine can also manage the deformation of the panels to provide reliable and stable results.

The TOP-F280 comes equipped with high-quality aluminum silicate, which provides optimal insulation that minimizes the amount of energy required, allowing for more efficient use of your resources. The machine is also user-friendly, featuring a user-friendly interface that makes it easy to adjust the settings to your requirements.

In conclusion, the TOP-F280 vacuum press machine is an excellent investment for any business that values quality, efficiency, and productivity. With its advanced features and stunning performance, you can enjoy a seamless experience in creating beautiful, unique products that stand out and impress. Get your TOP-F280 vacuum press machine today and discover the power of precision, quality, and efficiency!

OUR CERTIFICATES

| MODEL | TOP-F280 | |

|---|---|---|

| Selection | Standard edition | Extended version |

| Overall size | 9650*1780*1850mm | 11000*1780*1850mm |

| Working table | 2550*1300*50mm | 3000*1300*50mm |

| Working thickness | ≤80mm | ≤80mm |

| Total power | 37kw | 40.6kw |

| Net Weight | 2500kg | 2800kg |