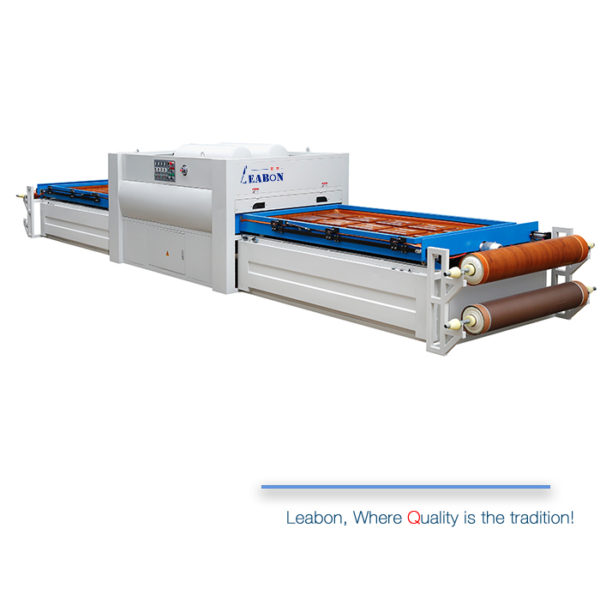

sdg10-13 profile curve surface sanding machine

SDG10-13 Profile Curve Surface Sanding Machine Features

PLC Converter Speed Control

Floating Structure

Patented Disc Quick Change Structure

Universal Modular Design

One-button start, the whole machine fully automatic digital control all adjustments, the operation is simple and convenient.

The system uses PLC to connect high-definition touch screen communication inverter to visual display, operation, adjustment, maintenance and indication.

The conveying workbench is fixed, the sanding unit is floating on the whole, and the pressing material is independent, which is convenient for multi-machine automatic connection.

One-key machine, hundreds of product code memory storage, suitable for a variety of different workpiece sanding quick adjustment.

The 3D data scanning of the feeding position, the sand roller automatically decelerates, effectively protecting the head and fail of the workpiece.

Product Description

Our profile curve surface brush sanding machine is specifically designed to provide a solution for sanding special-shaped workpiece planes and paint surfaces. It's an innovative solution that allows businesses to achieve top-quality finishing on their products with ease.

The profile curve surface brush sanding machine is a versatile sanding machine that can tackle even the most complex sanding jobs. Its advanced technology allows it to be used for a wide range of industries such as furniture, woodworking, and metalworking. This machine is perfect for sanding profiles, curves, and surfaces with precision, and can achieve a consistent finish with minimal effort.

One of the standout features of this machine is its adaptability. Its flexible design allows it to be customized to meet specific customer requirements, including different types of brushes, different brush densities, and speeds. This makes it a useful addition to the production line, as it can easily adapt to the needs of the user. It's easy to operate and maintain and can be set up to suit the user's preferred working conditions.

In conclusion, the profile curve surface brush sanding machine is the ideal solution for businesses looking to achieve high-quality sanding results with minimal effort. Its advanced technology, flexible design, and ease of use make it the ultimate sanding machine, suitable for a wide range of industries. So, why wait? Upgrade to the profile curve surface brush sanding machine today and take your finishing to the next level!

Our Certificates

| Equipment model | SDS13-T2A2P4L3 | SDG10/13-PPPPLL | SDT10/13-PPLLL | SDZ10/13-PPPLL |

| Workpiece width | 50~1300 mm | 50~1000/1300mm | 50~1000 /1300mm | 20~1000/1300 mm |

| Minimum length of workpiece | 380 mm | 450 mm | 380 mm | 350 mm |

| Workpiece thickness range | 10 ~ 150 mm | 10 ~ 150 mm | 10 ~150 mm | 5 ~ 150 mm |

| Lifting motor | 1.1 kW | 1×1.1 kW | 1x 1.1 kW | – |

| Conveying motor | 2.2kW | 2.2 kW | 1.5 kW | 1.5 kW |

| Feeding speed | 1 ~ 12m/min | 1~10 m/min | 1 ~10 m/min | 1 – 10 m/min |

| Servo motor power | 2×1.8kW | – | – | – |

| Flat disk sander | 2×1.5 kW 2×Φ180mm | – | – | – |

| Cross brush sander | 2×1.5 kW 4x Φ280mm | – | – | – |

| Brush disk sander | 2×1.5 kW 13x Φ180mm | 4×1.5 kW 9/11x Φ180mm | 2×1.5 kW 9/11x Φ180mm | 3groups 11/14 × Φ130mm |

| Long brush roller | 3 × 3kW Φ380 x1300mm | 2×1.5 kW Φ380 x1100/1300mm | 3x 1.5 kW Φ380 x1100/1300mm | 2groups Φ310 x1000/1300mm |

| Work pressure | 0.6-0.8mpa | – | – | – |

| Workable height | 845mm | 845mm | 845mm | 845mm |

| Vacuuming wind speed | 22m/s | 22m/s | 22m/s | 22m/s |

| Vacuum port | Φ125 x12pcs | Φ125 x10pcs | Φ125 × 8pcs | Φ125x5pcs |

| Total power | 27.8kW/380V 50HZ | 13.28kW/380V 50HZ | 12.2kW/380V 50HZ | 8.55kW/380V 50HZ |

| Dimensions (LxWxH) | 6200 × 2100 x2000mm | 4860 x1800/2100 x2000mm | 4000 x1800/2100 x2000mm | 3400 × 1800/2100 x1900mm |

| Weight | 6200kg | 4200/4500 kg | 2800/3000kg | 2000/2200kg |